Fromagex Products

From cultures to packaging, including equipment, here is our range of products.

Removable motor bridge with geared motor for domestic use

Stainless steel fork and squeegee for domestic use

Manual curd mill

Make cheese curds

The traditional cheese mill is a key part of the cheddar cheese curd process. It allows faster production for the cheesemaker.

Stainless Steel Aging Racks 630 x 510mm, 31 wires, H100/120mm (Plastic legs)

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Our wire stainless steel aging racks are used for ripening, brining and drying cheeses allowing an optimal ventilation and support of the products.

The choice of rack size should be done according to the cheese size and type.

They stack legs on legs to create shelves where the cheeses can be placed.

This modular solution will optimize the space in the room allowing an even result and an easy manipulation.

It suits well for fresh, soft and semi-soft cheeses, blue cheeses and other varieties that need to ripen or dry.

Made in #304 SS.

Assembly of the wires on the frame by food-grade spot welding.

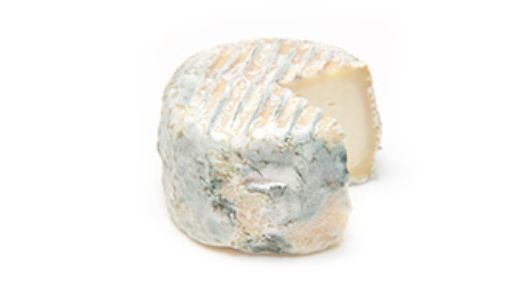

AL PE

Tear-resistant & sealable foil for blue cheese.

This aluminum-based structure controls gas exchanges.

This helps the development of cheese flavors and texture.

EASY-SET® A2070

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

Easy-Set A3050 Frozen 1000u

This Chr.Hansen EASY-SET® culture contains defined mesophilic and thermophilic strains and is for continous direct vat set use.

The strains are carefully composed to provide fast lactic acid production, extreme phage robustness and traditional (mesophilic) Cheddar flavor and texture development without any CO2 production (homofermentative).

The EASY-SET® A3000 program provides an unparallelled performance consistency between culture rotations.

EASY-SET® A940

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A945

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A2076

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A2041

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

Easy-Set A2130 Frozen 1000u

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A2065

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

Easy-Set A2090 Frozen 1000u

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A926

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A910

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

Easy-Set A2120 Frozen 1000u

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.

EASY-SET® A920

The culture is primarily applied in the production of Cheddar, Colby and Monterey Jack cheese.